Your cart is currently empty!

New in store

-

Sustainable Plantation Practices & ESG Compliance Course₱18,000.00

Sustainable Plantation Practices & ESG Compliance Course₱18,000.00 -

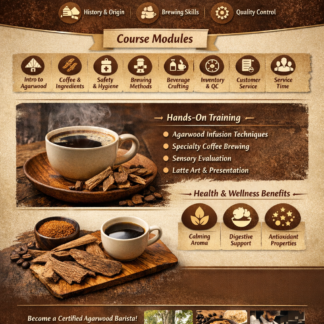

Agarwood Coffee Preparation Training Course₱20,000.00

Agarwood Coffee Preparation Training Course₱20,000.00 -

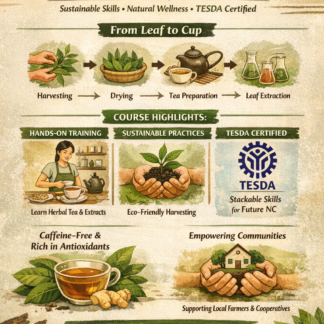

Agarwood Herbal Leaf Tea Preparation Training Course₱20,000.00

Agarwood Herbal Leaf Tea Preparation Training Course₱20,000.00 -

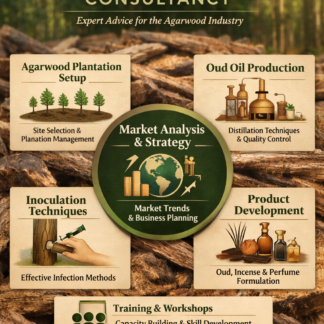

Agarwood Consultancy Services₱20,000.00

Agarwood Consultancy Services₱20,000.00